I. Executive Summary: The HV Connector Mandate

The automotive industry’s shift to high-voltage 800V architectures—driven by the need for ultra-fast charging and extended range—has fundamentally changed connector requirements. This isn’t an option; it’s a non-negotiable safety and reliability mandate. HV systems expose interconnects to extreme thermal and electrical stress, making the connector the single point of failure where a catastrophic arc flash can occur.

This technical guide, from Suzhou Suqin Electronic Technology Co., Ltd. (Suzhou Suqin Electronic), asserts that 800V sourcing must meet three non-negotiable specifications: IP69K environmental sealing, integrated HVIL safety, and 360° EMI shielding. We detail the proven solutions from market leaders like Amphenol and TE Connectivity and emphasize the supplier diligence required for genuine, reliable components in this high-stakes environment.

II. Technical Mandates: IP69K, Safety, and Shielding

The reliability of a high-voltage system hinges on the connector’s ability to resist external damage and prevent internal electrical failures.

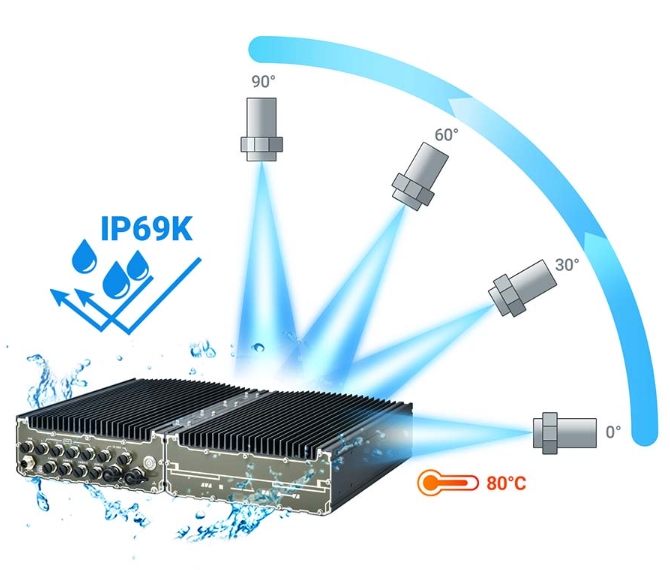

2.1 Environmental Resilience: Why IP69K is the Baseline

Engineers must recognize the limitations of traditional IP67. While IP67 only guarantees temporary immersion protection, modern EVs and heavy equipment require protection against sustained, aggressive cleaning. The shift to IP69K is essential because this rating certifies the connector’s ability to withstand high-pressure, high-temperature water jets and steam cleaning—conditions that would quickly compromise a lesser seal. Products like the Amphenol AT Series meet this standard, ensuring the integrity of the crucial HV connections under the hood or chassis where exposure is constant

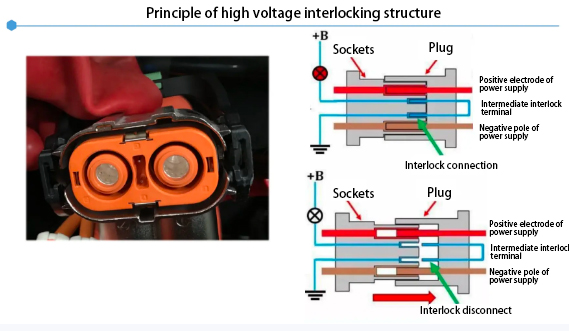

2.2 Safety First: HVIL and Arc Flash Prevention

At 800V potential, even a momentary disconnect can result in a dangerous arc flash. This is why the High-Voltage Interlock Loop (HVIL) is non-negotiable. The HVIL system is designed to verify the connector is fully mated before allowing the high-voltage circuit to be energized, and instantaneously cuts power if the connection is disturbed, preventing electrical shock hazards. 2 Leading suppliers, including TE Connectivity, integrate this feature directly within the plug, as seen in the AMP+ HP 800 Series, which is rated up to 1000V and 250A and includes touch-safe technology to protect personnel.

2.3 The Necessity of 360° EMI Shielding

The high-current flow in 800V architectures generates substantial Electromagnetic Interference (EMI) that can corrupt critical data signals. A quality HV connector must provide 360° shielding to protect these circuits.3 Industry standards often mandate that the shielding circuit resistance be less than 10 milliohms ($10\text{m}\Omega$), a critical benchmark for ensuring data integrity and system stability

III. Sourcing Assurance: Mitigating Supplier Risk

In the high-risk 800V supply chain, the sourcing partner is just as critical as the component itself. Trust and traceability are non-negotiable.

3.1 Choosing Authenticity Over Risk

- The Sourcing Imperative: Engineers designing 800V systems must rely on components from manufacturers known for consistent quality and innovation, such as Amphenol, TE, Molex, and Deutsch. Using counterfeit or off-specification products in these high-power applications can lead directly to catastrophic thermal and safety failures.

- Our Guarantee: Suzhou Suqin Electronic Technology Co., Ltd. (Suzhou Suqin Electronic) eliminates this risk by providing a 100% genuine guarantee for every part sourced. This commitment to authenticity is foundational to maintaining safety standards.

3.2 Guaranteeing Quality Management: The IATF 16949 Pledge

Automotive Standards: Our commitment extends beyond the product itself. We are continuously dedicated to achieving IATF 16949 compliance , a signal to automotive clients that our internal quality management systems—from handling to logistics—meet the industry’s most stringent requirements.

Risk Mitigation Services: To support procurement teams, we back our sourcing expertise with a 15-day refund service for any quality issues. This ensures that quality control extends to the final point of delivery, providing crucial assurance in a complex supply chain.

IV. Conclusion: Partnering for EV Safety

The transition to 800V EV platforms mandates the use of highly specialized, IP69K, HVIL-integrated interconnects. For engineering teams under pressure to deliver performance, Suzhou Suqin Electronic acts as the crucial link, guaranteeing the genuine Amphenol and TE components necessary for safety, backed by a commitment to IATF 16949 standards and unwavering supply chain integrity.

Post time: Nov-06-2025