As EVs and AVs demand unprecedented reliability, connector standards evolve beyond IP67 to meet harsh reality. Here’s what engineers and procurement specialists need to know.

The electric and autonomous vehicle revolution is built on a simple premise: reliability. While batteries and sensors capture headlines, it’s the automotive electrical connector—often overlooked—that ensures power and data flow flawlessly. But not all connectors are created equal. As OEMs push the boundaries of performance, a critical shift is underway from the industry-familiar IP67 rating toward the more robust IP6K9K standard. This isn’t just a technicality—it’s a response to real-world failures in extreme conditions. For engineers specifying components and procurement teams evaluating suppliers, understanding this evolution is essential.

The Limitations of IP67 in Modern Automotive Applications

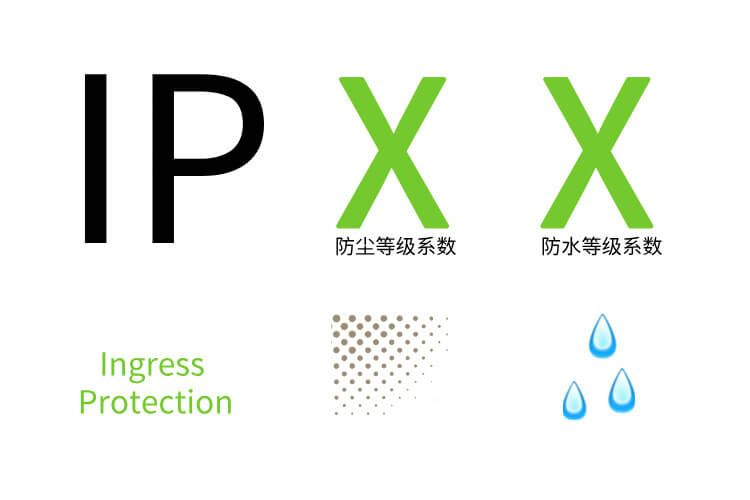

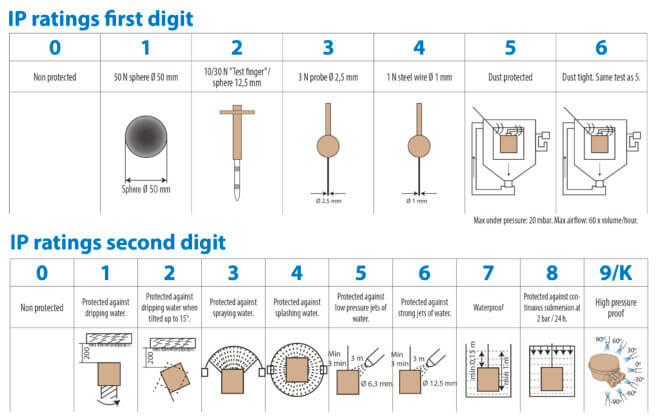

The IP67 rating has long been a trusted benchmark. It guarantees protection against dust ingress and immersion in water up to 1 meter for 30 minutes. For years, it sufficed for interior electronics and sealed enclosures.

However, the operating environment for EVs and AVs is far more demanding. Consider:

- Autonomous sensor suites (LiDAR, radar, cameras) mounted externally face direct exposure to high-pressure car washes, road spray, and abrasive debris.

- EV charging inlets must withstand not just rain but aggressive cleaning protocols and incidental impact.

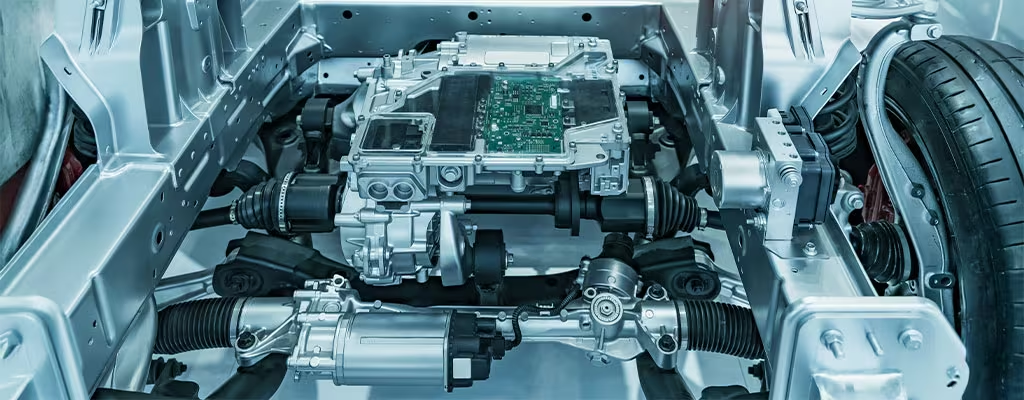

- Underhood and underbody locations experience extreme temperatures, vibration, and corrosive agents.

IP67 testing—static immersion at ambient temperature—does not replicate these conditions. This gap has led to field failures, warranty claims, and recalls—prompting a reevaluation of connector standards.

IP6K9K: Designed for Automotive’s Harsh Realities

The IP6K9K standard addresses these shortcomings with testing that mirrors actual use cases:

- High-pressure, high-temperature jets (80-100 bar, 80°C) simulate industrial wash-downs and road spray.

- Multi-angle spraying (0°, 30°, 60°, 90°) ensures complete coverage.

- The same dust-tight integrity as IP67 (6K rating).

This isn’t an incremental improvement—it’s a step change in reliability. Connectors rated IP6K9K undergo testing that is both more severe and more relevant to automotive applications. For manufacturers of automotive connector housings and accessories, this has become a key differentiator in proposals for Tier 1 and OEM business.

Data-Driven Decision Making: When to Specify IP6K9K

Not every application requires IP6K9K. Based on industry failure mode analysis and warranty data, here are clear guidelines:

Specify IP67 for:

- Interior cabin electronics (infotainment, control units).

- Components within sealed battery enclosures (BMS connections).

- Environments with potential splash but no high-pressure exposure.

Require IP6K9K for:

- EV charging inlets and ports (subject to high-pressure washing).

- Exterior autonomous driving sensors (LiDAR, radar, cameras).

- Underhood and under-chassis components (exposed to road spray and cleaning).

- High-voltage interlock loops (HVILs) where failure is safety-critical.

For procurement teams, this translates into clearer sourcing criteria and reduced risk of field issues.

The Broader Implications: Supply Chain and Sourcing

This shift has ripple effects beyond engineering. Suppliers of automotive connector accessories must now provide:

- Certified test data from accredited laboratories.

- Material specifications ensuring performance at elevated temperatures.

- Compatibility with automated assembly processes.

OEMs are increasingly mandating IP6K9K for exterior components—making it a de facto requirement for new business. Suppliers who proactively adapt will gain a competitive edge.

Conclusion: Reliability as a Competitive Advantage

The move from IP67 to IP6K9K is more than a technical upgrade—it’s a reflection of the automotive industry’s increasing maturity. As vehicles become more electrified and autonomous, the tolerance for failure diminishes. Connectors are no longer just components; they are critical enablers of functionality and safety.

For engineers and procurement specialists, the message is clear: specify for the real world, not the test bench. The right choice isn’t just about avoiding failures—it’s about building trust in every vehicle that rolls off the line.

Post time: Sep-17-2025