When it comes to automotive electrical systems, choosing the right automotive terminals is crucial for ensuring reliable performance, safety, and longevity. Whether you’re working on a car, truck, or motorcycle, selecting the correct wire terminals, AMP connectors, and other electrical components can make all the difference.

In this guide, we’ll explore the key factors to consider when choosing automotive terminals, helping you make an informed decision for your vehicle’s electrical needs.

1. Understand the Different Types of Automotive Terminals

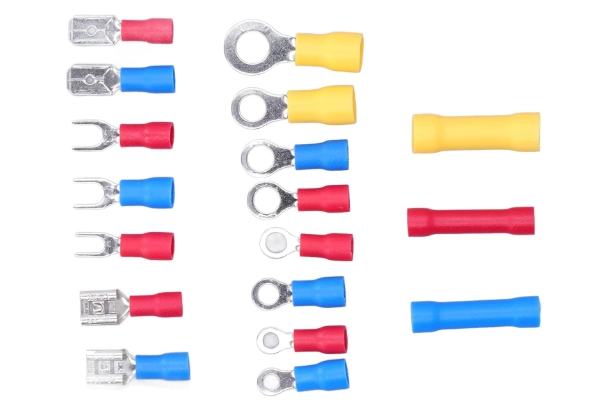

Automotive terminals come in various shapes, sizes, and materials, each designed for specific applications. Some of the most common types

include:

Ring Terminals

Ideal for secure connections to studs or bolts

Available in insulated and non-insulated versions

Commonly used in battery and grounding applications

Spade Terminals (Fork Terminals)

Easy to install and remove

Used in fuse boxes, relays, and switches

Available in different widths (e.g., 0.25″, 0.5″)

Butt Connectors

Used to splice two wires together

Available in heat-shrink and insulated versions

Ensures a strong, weatherproof connection

AMP Connectors (Automotive Multi-Pin Connectors)

Used in complex wiring harnesses

Provides secure, multi-wire connections

Often found in sensors, ECUs, and lighting systems

2. Consider Wire Gauge and Terminal Size

Matching the wire terminal size to your wire gauge is essential for a secure connection. Using an undersized terminal can lead to poor conductivity, while an oversized one may not grip the wire properly.

Check the AWG (American Wire Gauge) rating of your wire before selecting a terminal.

Use crimping tools designed for the terminal type to ensure a solid connection.

3. Choose the Right Material for Durability

Automotive terminals are exposed to heat, moisture, and vibration, so material selection is critical:

Copper terminals – Excellent conductivity but may corrode over time.

Tin-plated terminals – More corrosion-resistant than bare copper.

Nickel-plated terminals – Best for high-temperature environments.

For added protection, consider heat-shrink terminals with adhesive lining to prevent moisture ingress.

4. Ensure Proper Crimping and Installation

A poorly crimped terminal can lead to electrical failures. Follow these best practices:

Use a quality crimping tool (ratcheting crimpers provide consistent pressure). Strip the wire to the correct length (too much or too little exposed wire can cause issues). Inspect the crimp – A proper crimp should be tight with no loose strands.

5. Check for OEM Compatibility

If you’re replacing factory wiring, ensure the automotive terminals match the original specifications. Some vehicles use proprietary AMP connectors or specialized terminals that require exact replacements.

Final Thoughts: Choosing the Best Automotive Terminals

Selecting the right automotive terminals ensures a reliable electrical system, reduces the risk of failures, and extends the lifespan of your vehicle’s wiring. By considering terminal type, wire gauge, material, and installation quality, you can make the best choice for your automotive needs.

Post time: Apr-17-2025