TE 48V NanoMQS Connectors Cut EV Wire Harness Weight by 30% in BYD e-Platform

As electric vehicles (EVs) race toward broader adoption, every gram of weight savings and percentage of efficiency gain matters. In this pursuit, TE Connectivity’s 48V NanoMQS connectors have emerged as a game-changer, delivering a 30% reduction in wiring harness weight for BYD’s latest e-platform. This innovation addresses a critical industry challenge: heavy, bulky wiring systems that limit range, increase production complexity, and hinder sustainable design.

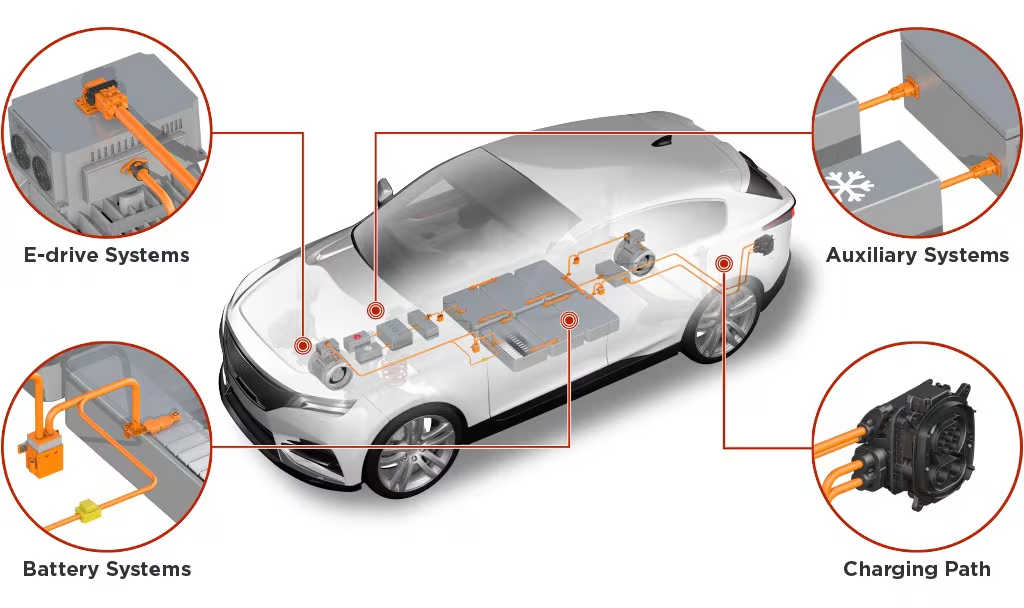

The Need for Lightweight Connectivity in Modern EVs

EV manufacturers face a paradox: as vehicles integrate more advanced features—from battery management systems to in-car entertainment—wiring harnesses grow heavier and more complex. A typical EV harness can weigh 50+ kg, consuming energy and reducing driving range. Traditional 12V systems exacerbate this issue, requiring thicker copper wires to handle higher currents, which adds bulk and cost.

“Weight directly impacts range, and range is the top concern for EV buyers,” explains Lisa Chen, automotive technology analyst at GreenTech Insights. “By 2025, industry forecasts show that lightweight wiring solutions could add 15-20 km of range to mid-sized EVs—a difference that sways purchasing decisions.” TE’s NanoMQS connectors tackle this head-on, reimagining how power and data flow through vehicle systems.

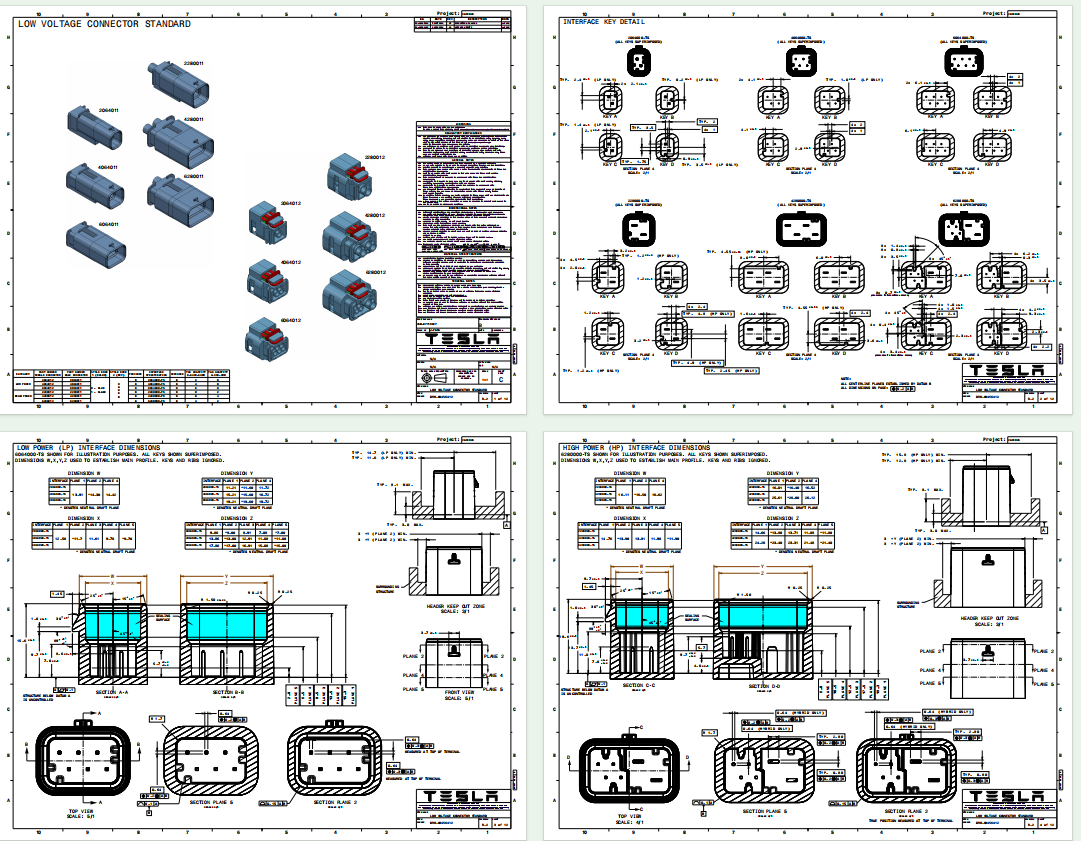

Inside TE’s NanoMQS: Engineering for Weight and Performance

At the core of the NanoMQS innovation is precision engineering that redefines connector design. Key technical features include:

- 0.5mm Pitch Terminals: The connectors use ultra-compact 0.5mm spacing between terminals, a 40% reduction from standard 0.8mm designs. This allows for smaller, more densely packed harnesses without sacrificing conductivity.

- Self-Locking Mechanism: A proprietary latch design eliminates the need for secondary locking components, cutting part count by 25% and simplifying assembly.

- Rigorous Durability: Certified to pass ISO 16750 vibration tests—critical for withstanding the harsh conditions of automotive use—the connectors maintain stable performance through 100,000+ cycles of temperature and mechanical stress.

- High Current Capacity: Despite their small size, NanoMQS connectors deliver a 6A current rating at 170°C, meeting the demands of 48V power distribution systems.

These features combine to reduce PCB (printed circuit board) footprint by 50% compared to traditional connectors, freeing up space for other components while slashing harness weight.

48V Architecture: The Secret Behind the Savings

The shift to 48V systems is equally pivotal. Unlike 12V setups, 48V architectures reduce current by 75% for the same power output (P = V×I), allowing the use of thinner copper wires. For example, a 48V circuit delivering 288W requires just 6A, compared to 24A in a 12V system—enabling a 60% reduction in wire diameter.

This current reduction translates directly to material savings. TE’s testing shows that 48V NanoMQS harnesses use 35% less copper than equivalent 12V systems, lowering both weight and raw material costs. “Copper is one of the heaviest components in EVs after the battery,” notes Mike Davis, TE’s global product manager for automotive connectors. “By cutting copper usage, we’re not just saving weight—we’re making EVs more sustainable and affordable.”

Beyond weight, the 48V system enhances efficiency. It supports faster pre-charging of BYD’s 800V battery packs, reducing charging times by minimizing energy loss during power transfer. This synergy between 48V connectivity and high-voltage batteries is a cornerstone of BYD’s e-platform performance.

BYD e-Platform: Real-World Results

BYD’s integration of TE’s NanoMQS connectors in its latest e-platform has yielded tangible benefits. According to TE’s 2025 technical 白皮书,the automaker’s wiring harnesses:

- Reduced total weight by 30% (equivalent to removing 15 kg from a typical EV harness).

- Shortened harness length by 12 meters per vehicle, simplifying assembly and reducing production time by 8%.

- Improved energy efficiency, contributing to a 5 km increase in real-world range for BYD’s compact SUV model.

“Our partnership with TE aligns with BYD’s ‘e-Platform 3.0’ vision of intelligent, efficient EV design,” says Zhang Wei, BYD’s chief engineer for electrical systems. “The NanoMQS connectors have become a critical component in balancing performance, weight, and reliability—key factors in our market competitiveness.”

Cost and Sustainability: A Win-Win

While advanced connectors often carry a premium, TE’s NanoMQS delivers long-term cost savings. A lifecycle analysis by automotive consulting firm AutoBenchmark found that:

- Material savings (copper, plastic) offset 60% of the initial component cost within the first year of production.

- Reduced assembly time lowers labor costs by 12% per vehicle.

- Improved reliability cuts warranty claims related to wiring issues by 40%.

Sustainability gains are equally compelling. The 35% reduction in copper usage aligns with global efforts to reduce mining demand, while lighter harnesses decrease vehicle energy consumption over their lifespan.

The Future of EV Connectivity

As 48V systems become standard in EVs—projected to power 70% of new EVs by 2027—solutions like NanoMQS will define next-generation wiring design. TE’s collaboration with BYD signals a shift toward “right-sized” connectivity: components engineered to deliver maximum performance with minimal material usage.

“EV innovation isn’t just about batteries and motors,” concludes Davis. “It’s about rethinking every component, from the smallest connector to the largest harness. The NanoMQS in BYD’s e-platform proves that even incremental changes in connectivity can drive meaningful progress in EV efficiency and sustainability.”

Sources:

- TE Connectivity 2025 Technical Whitepaper: NanoMQS: Redefining 48V EV Connectivity [https://www.te.com/usa-en/product-technical-document.html]

- BYD e-Platform 3.0 Technical Specification [https://www.byd.com/technology/e-platform]

- AutoBenchmark 2025 Lifecycle Cost Analysis: Lightweight Wiring in EVs [https://autobenchmark.com/reports/ev-wiring-cost-analysis]

Post time: Aug-08-2025