Winter weather doesn’t just test your EV’s battery range—it’s a silent threat to one of its most critical components: the connectors. As temperatures plummet, these small but vital parts face a perfect storm of stressors that can leave you stranded at the charger or with unexpected breakdowns. The National Renewable Energy Laboratory (NREL) puts it plainly: “Cold climates highlight connectors as the Achilles’ heel of EV performance.” Here’s why winter wreaks havoc on your EV’s connectors, and exactly how to keep them reliable.

Why EV Connectors Struggle in Winter

It’s not just “the cold”—it’s a combination of three damaging factors that target connectors’ design and materials:

1. Material Contraction Breaks Contact

Connectors rely on tight, precise fits between metal terminals and plastic housings. When temperatures drop below freezing, these materials shrink at different rates: metals contract slightly, while plastics harden and pull away from terminals. The result? Loose connections that boost electrical resistance, slow charging speeds, or even cut power entirely.

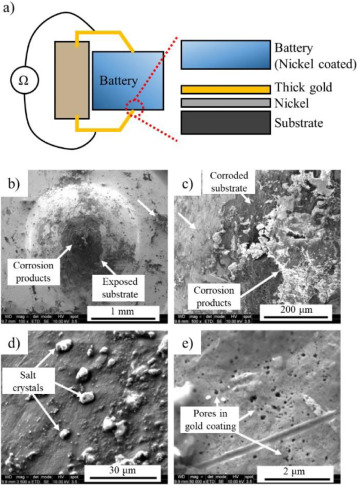

This isn’t just a theoretical risk. In 2022, GMC recalled 424 Hummer EVs specifically because their high-voltage connectors failed in winter: cold-induced contraction created gaps that let moisture seep in, leading to corrosion and electrical shorts.

2. Moisture + Ice Destroys Internal Parts

Winter brings snow, slush, and melting ice—all of which find their way into tiny gaps in connector housings. Once inside, water freezes and expands, cracking plastic components, bending terminals, and ruining seals. Even a small ice buildup can block current flow or cause permanent damage.

Industry standards now reflect this risk: The IEC 62196-3 specification for DC connectors explicitly mandates “enhanced sealing” for cold-weather use, recognizing that basic waterproofing isn’t enough when water turns to ice.

3. Thermal Stress Causes Hidden Cracks

Every time you plug in your EV in winter, the connector goes through a brutal cycle: frigid (often below -10°C) to hot (from charging current) in minutes. This repeated heating and cooling weakens solder joints and creates micro-cracks in terminals. Over weeks or months, these cracks grow—until one day, the connector stops working entirely.

3 Proven Ways to Prevent Winter Connector Failures

You don’t have to accept winter connector issues as inevitable. Here’s how to protect your EV:

1. Upgrade to Winter-Rated Connectors

Not all connectors are built for cold weather. Look for options rated to handle sub-zero temperatures:

- Hirose ZE064W Series: These waterproof connectors work reliably from -40°C to 125°C, with reinforced seals that block snowmelt and slush. They’re a favorite for EVs in Northern Europe and Canada.

- Molex Automotive High-Voltage Connectors: Designed for extreme temperature swings, they use flexible materials that resist contraction and maintain tight fits even when it’s freezing.

If you’re buying a new EV, ask the dealer: “Are the charging and battery connectors winter-rated?” It’s a simple question that can save you headaches later.

2. Do This 5-Minute Winter Maintenance Check

A quick monthly inspection is enough to catch issues before they escalate:

- Inspect seals: Look for cracks or wear on the connector’s rubber gaskets (around the plug and where it attaches to the EV). If they’re damaged, replace them immediately—seals are cheap, but a failed one can cost hundreds in repairs.

- Apply dielectric grease: A thin layer of dielectric grease (available at auto parts stores) on the connector’s terminals creates a barrier against moisture. It won’t affect conductivity, but it will stop water from seeping in and freezing.

- Wipe it down: After charging in snow or slush, dry the connector with a clean cloth. Ice buildup starts with wet surfaces—don’t let it sit.

3. Take Advantage of New Policy Support

If you’re a charger owner or live in a cold region, good news: The 2025 Inflation Reduction Act (IRA) now includes subsidies for EV chargers equipped with winter-ready connectors. This means more public chargers will soon have the same heavy-duty, cold-resistant connectors that protect high-end EVs—making it easier to charge reliably, even on snowy days.

The Bottom Line

Winter doesn’t have to be a nightmare for your EV’s connectors. By choosing the right components, doing quick maintenance, and leveraging new industry standards, you can keep your EV running smoothly—no matter how low the temperature drops. As NREL notes, “Reliable EVs in cold climates start with reliable connectors.” Don’t overlook this small part—it’s the key to stress-free winter driving.

Post time: Sep-12-2025