Terminal crimping is a common electronic connection technology, but in practice, it often encounters bad connections, wire breakage, and insulation problems. By selecting the appropriate crimping tools, wires, and terminal materials, and following the correct operating methods, these problems can be effectively resolved to ensure the quality and reliability of terminal crimping. At the same time, for complex or demanding crimping tasks, it is recommended to seek professional help and guidance to ensure the stability and safety of the connection.

Ⅰ.Poor contact problems:

1.Poor crimping: The cause of poor connections may be insufficient crimping effort or the use of inappropriate crimping tools.

Solution: Ensure the use of appropriate crimping tools, in accordance with the manufacturer’s recommended crimping strength for the operation, and regular quality checks.

2.Loose wire: The wire may be loose after crimping, resulting in unstable current transmission.

Solution: Check whether the crimping is even, and use the appropriate size terminals and wires for connection.

Ⅱ.Wire breakage problems:

1.Excessive crimping: Excessive crimping may result in wire breakage as the wire is subjected to excessive stress.

Solution: Confirm the crimping strength of the crimping tool before crimping and avoid over-crimping.

2.Unsuitable wire selection: Use of unsuitable wire materials or specifications may result in wire breakage.

Solution: Select the appropriate wire materials and specifications to meet the requirements of the current and environmental conditions.

Ⅲ.Insulation problems:

1.Insulation Breakage: Insulation may be damaged during terminal crimping, resulting in a short circuit or poor insulation.

Solution: Ensure that the insulation is intact before crimping and use proper crimping tools and techniques for the operation.

2.Insulating materials are not high-temperature resistant: some insulating materials may not be resistant to high temperatures, resulting in a decline in insulation performance in high-temperature environments.

Solution: Choose high-temperature-resistant insulating materials and crimp the terminals according to the environmental requirements.

IV. Other problems:

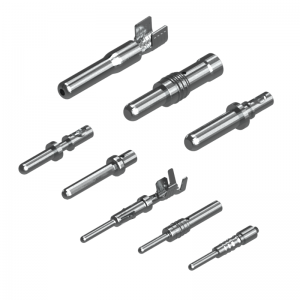

1. Improper terminal selection: The selection of unsuitable terminals or poor-quality terminals may result in unstable connections or failure to adapt to specific environments.

Solution: Select the appropriate terminals according to the actual needs and ensure that they comply with the relevant standards and norms.

2. Incorrect operation: Incorrect operation methods may lead to terminal crimping problems.

Solution: Provide correct training and guidance to ensure that operators are familiar with the correct terminal crimping technology and operating procedures, reasonable debugging, and calibration of crimping equipment to ensure the stability of the equipment work.

Post time: Aug-24-2023