1. What is a PCB connector

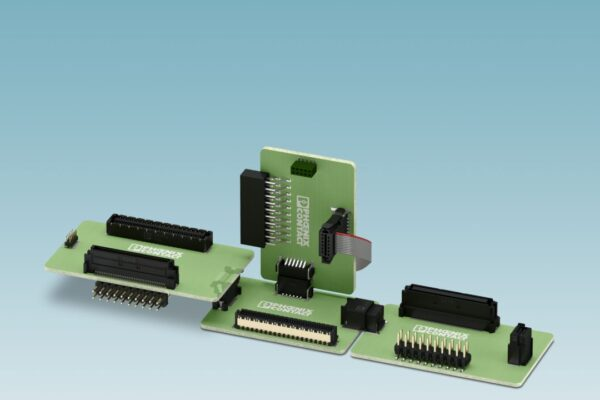

A printed circuit board connector, also called a PCB connector, is a kind of electronic connector, specially used to connect and fix the printed circuit board connection devices, usually using pin press-in type, with super FPC cable clamping force.

The plug (insert) and socket (seat) are two parts, through the plug and socket between the plug to achieve electrical connection or disconnection. Widely used in electronic equipment, communication equipment, automotive electronics, industrial control equipment, medical equipment, and other fields.

2.What are the functional roles?

1)Electrical connection: Plugs and sockets through the plug and socket to achieve electrical connection or disconnection, to achieve the signal transmission and power transfer between the circuit board or between the wire and the circuit board.

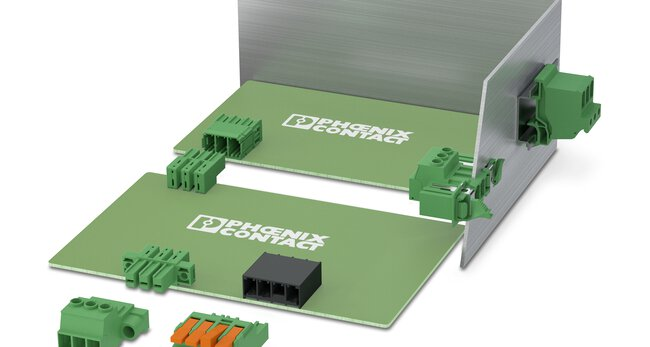

2)Mechanical fixing: With the mechanical fixing function, it can fix the plug and socket firmly on the PCB board to ensure the reliability and stability of the connection.

3)Space-saving: Compact design to realize circuit connection in limited space, thus saving the space of PCB board.

(4) Plugging performance: Need to have good plugging performance, can be frequently plugged and unplugged in the case of maintaining a stable electrical connection to meet the needs of the equipment.

3. How should I pick the right PCB?

1)PCB connector form factor

Small connector product footprint simplifies PCB design, reduces cost, and reduces transmission loss while enabling connection from point A to point B. The small contact pitch makes the connector thinner and has more convenient smaller circuit boards and backplanes.

2)Signal loss rate of circuit board connectors

With the exponential rise in data rates, how to reduce insertion loss is a great concern for manufacturers. The internal structure as well as the contacts inside the connector play an important role in improving signal integrity and minimising insertion loss. In addition, the connector can also enhance the signal interface by improving airflow and channel impedance.

3)EMI and ESD shielding of circuit board

At higher data rates, shielding electromagnetic interference (EMI) and electrostatic discharge (ESD) has become increasingly important, the physical envelope as well as special installation and termination mechanisms ensure that the prevention of EMI and ESD effects play an important role.

4)Cable termination of PCB connectors

This is the transition point where the cable is terminated with the connector, which helps to reduce signal loss. For example, some PCB connectors come with pre-loaded springs to prevent accidental cable removal, and the connector integrates the wire termination unit and cable clamps into a plug housing.

5)Mechanical strength of circuit board connectors

A flexible, robust, and durable connector design means that it can withstand cable tension, heat, shock, vibration and other external forces. The mechanical strength of PCB connectors also ensures proper mating and connection security.

4. Future technology development trend

Circuit board connectors are important components that connect the electrical and mechanical parts between electronic devices. With the popularity and large-scale application of electronic devices the popularity and large-scale application of electronic devices, the PCB connector industry has gradually become a rapidly developing and mature market.

With the continuous development of intelligence and automation, the demand for Printed Circuit Board connectors has increased in the fields of household appliances, automotive electronics, communications, medical devices, security monitoring, etc. In addition, to the promotion of the 5G network, the application of communication equipment demand is also growing significantly. Global demand for electronic equipment continues to expand, and the PCB connector market demand is also gradually showing a diversified, personalized trend.

The growing competition in the electronics market, so that the circuit board design and manufacturing technology is constantly advancing, for the production process and the development of intelligent manufacturing solutions need to be further upgraded to better meet future market demand.

Post time: Sep-28-2023