With the current continuous development of electric vehicles, more and more technicians and users are paying more and more attention to the high-voltage safety of electric vehicles, especially now that higher platform voltages (800V and above) are continuously applied. As one of the measures to ensure the high voltage safety of electric vehicles, the high voltage interlock (HVIL) function has been increasingly emphasized, and the stability and response speed of the HVIL function are being improved continuously.

High Voltage Interlock (HVIL for short), is a safety design method to manage high voltage circuits with low voltage signals. In the design of the high-voltage system, to avoid the arc caused by the high-voltage connector in the actual operation of the process of electric disconnecting, and closing, a high-voltage connector should generally have a “high-voltage interlock” function.

A high-voltage connection system with high-voltage interlocking function, power, and interlocking terminals should meet the following conditions when connecting and disconnecting:

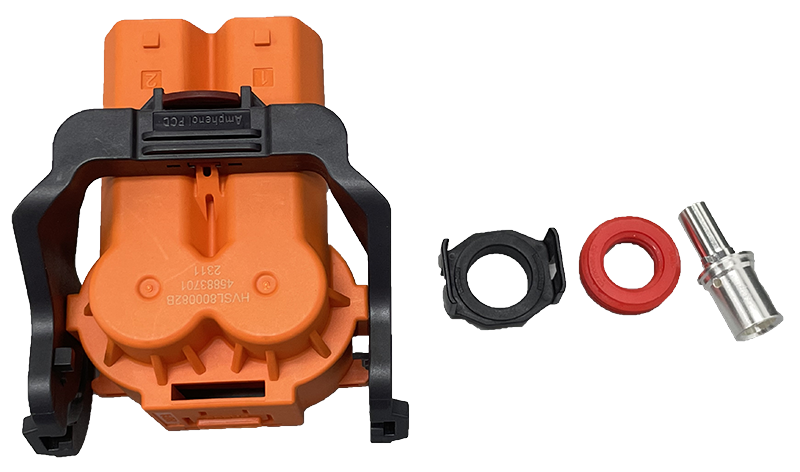

When the high-voltage connection system is connected, the power terminals are connected first and the interlocking terminals are connected later; when the high-voltage connection system is disconnected, the interlocking terminals are disconnected first and the power terminals are disconnected later. That is to say: the high voltage terminals are longer than the low voltage interlock terminals, which ensures the effectiveness of the high voltage interlock signal detection.

High-voltage interlocks are commonly used in high-voltage electrical circuits, such as high-voltage connectors, MSDs, high-voltage distribution boxes, and other circuits. Connectors with high-voltage interlocks can be disconnected by the logic timing of the high-voltage interlock when unlocking is performed under power, and the time of disconnection is related to the size of the difference between the effective contact lengths of the high-voltage interlock terminals and the power terminals and the speed of disconnection. Usually, the response time of the system to the interlocking terminal circuit is between 10 ~ and 100ms when the connection system separation (unplugging) time is less than the system response time, there will be a safety risk of electrified plugging and unplugging, and the secondary unlocking is designed to solve the problem of this disconnection time, usually, the secondary unlocking can effectively control this disconnection time of more than 1s, to ensure the safety of the operation.

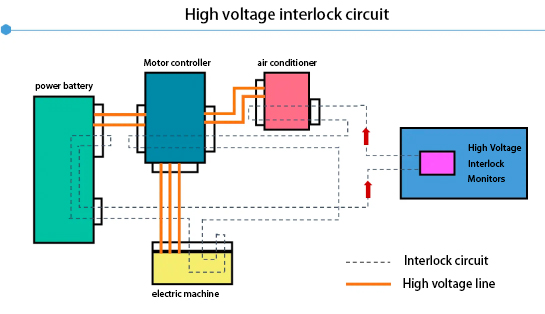

The issuance, reception, and determination of the interlock signal are all realized through the battery manager (or VCU). If there is a high-voltage interlock fault, the vehicle is not allowed to go on high-voltage power, and the interlock circuits of different car models have certain differences (including differences in the interlock pins and high-voltage parts included in the interlock).

The above figure shows a hardwired interlock, using a hardwire to connect the feedback signals from each high-voltage component connector in series to form an interlock circuit, when a high-voltage component in the circuit fails to interlock, the interlock monitoring device will immediately report to the VCU, which will execute the corresponding power down strategy. However, it should be noted that we can’t let a high-speed car suddenly lose power, so the speed of the car must be taken into account in the execution of the power-down strategy, so the hard-wired interlocks must be graded when the strategy is formulated.

For example, BMS, RESS (battery system), and OBC are classified as level 1, MCU and MOTOR (electric motor) as level 2, and EACP (electric air conditioning compressor), PTC, and DC/DC as level 3.

Different HVIL strategies are adopted for different interlocking levels.

Since the high-voltage components are distributed throughout the vehicle, this leads to a very long interlock hardwire length, resulting in complex wiring and increased cost of low-voltage wiring harnesses. However, the hardwire interlocking method is flexible in design, simple in logic, very intuitive, and conducive to development.

Post time: Jan-26-2024